Corrosion

We give you full support

The simplest basic test instrument for determining metal and finishing corrosion resistance. SUGA, which is applicable to ISO 09227 and others, aims for consistency and repeatability in outcomes.

Salt Spray Test Instrument / CASS Test Instrument / Humidity Test Instrument

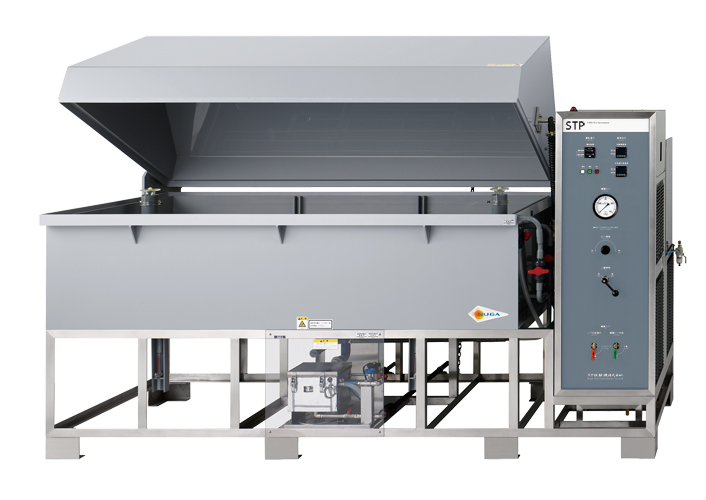

Salt Spray Test Instrument STP-90V-6

Compact New model

This is the most basic test instrument for determining the corrosion resistance of metals and surface treatment. The solution is sprayed from the mist dispersion tower, a method recommended by ISO for its uniform distribution capability. An air barrier board is set inside the solution tank, preventing the fluctuation of the solution’s pH level.

*Product image for illustration purposes only.

CASS Test Instrument CAP-90V-6

Compact New model

This is the most basic test instrument for determining the corrosion resistance of metals and surface treatment. The solution is sprayed from the mist dispersion tower, a method recommended by ISO for its uniform distribution capability. An air barrier board is set inside the solution tank, preventing the fluctuation of the solution’s pH level.

*Product image for illustration purposes only.

Salt Spray Test Instrument STP-30

Table-top type with compact design.

STP-30 is not only able to be installed in a small space such as a table but also can perform on ISO 9227:2017 which is the most basic salt spray test method among corrosion acceleration tests to evaluate the corrosion resistance of metallic materials. It is widely used for quality control and acceptance inspection.

Salt Spray Test Instrument STP-200 / CASS Test Instrument CAP-200

Tests multiple / large-sized specimens at once

These instruments are capable of testing large number of specimens with its large-sized test chamber. The increased floor load resistance option allows the instrument to test large-sized specimens and full-scale and products.

Salt Spray Test Instrument STP-90VR

STP-90VR is capable of even distribution of salt spray test solution onto the specimen at a precision much greater than before.

Humidity Cabnet CT-3

Our standard model acknowledged as the leader in humidity testing

This is a test instrument for evaluating the humidity resistance of paint (ISO 6270), rust preventive oil (JIS K 2246), and metal surface treatments such as coating and colorants. Its chamber lid designed so that water particles adhered on the ceiling will not fall onto the specimens, giving it outstanding test reproducibility.

Ozone Weather Meter / Gas Test Instrument / G's Oven

Gas Test Instrument GS-UVS

It operates a programmed temperature-humidity test using an automatically controlled gas mixture of SO2, H2O and NO2, without any leakage from the walls in the apparatus chamber.

Gas Test Instrument GT-100

Instrument capable of accommodating tests with and without Cl2

GT-100 is used to evaluate the corrosion resistance of electronic components and plated products against pure or mixed gases of SO2, H2S, NO2 and Cl2. Exchangeable test Chamber for both conducting test using chlorine as well as tests not using chlorine. More stable control of the gas density, temperature, and humidity by preventing condensation system.

Ozone Weather Meter OMS-HN・OMS-LN

True ozone control made possible with pursuit of accuracy

This instrument performs accelerated ozone degradation testing for organic materials (such as rubber) used in automobiles and electronic materials. Its fully closed system allows for true ozone concentration tests. Applicable to ISO 1431-1 standard.

Corrosion Test Instrument Peripherals

Automatic Solution Supplying Unit SS-2

Contributes to reducing energy consumption in the solution supplying process

This unit automatically detects the water level in the corrosion test instrument’s solution tank, and supplies water when necessary. This is best suited for tests that take long period of time. It includes an air barrier board, which prevents the pH level of the solution from changing. SS-2’s water tank can hold up to 100 liters. Models with more solution capacity and capability of generating solutions are also available.